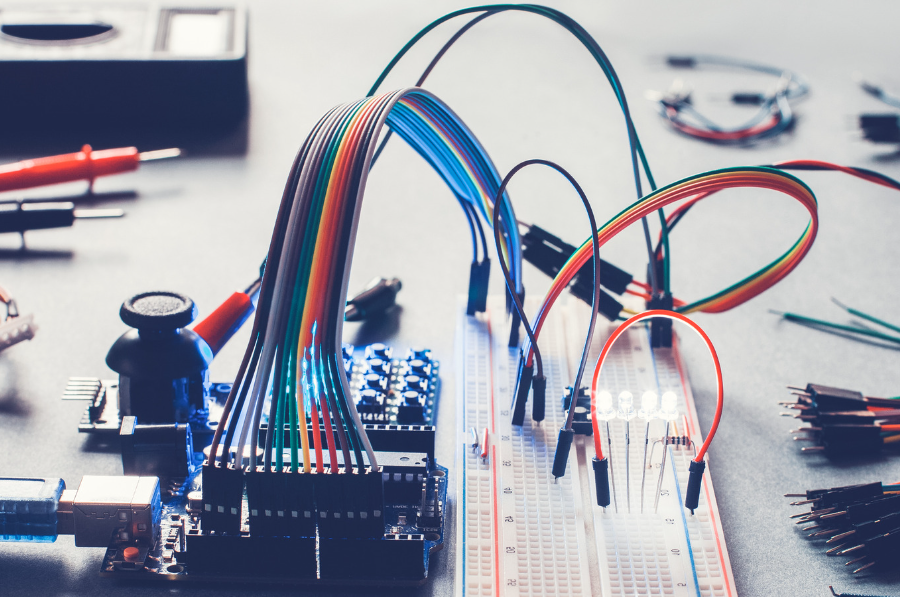

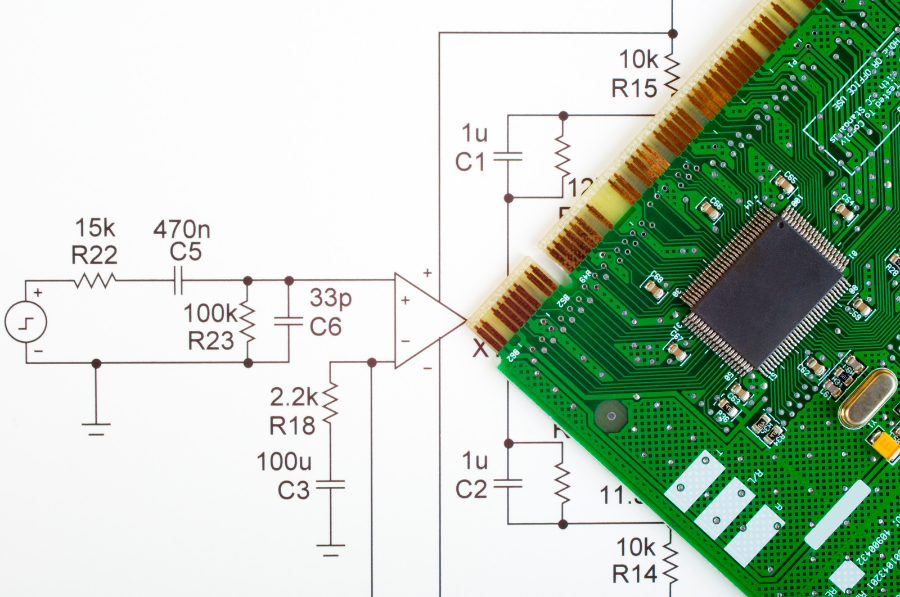

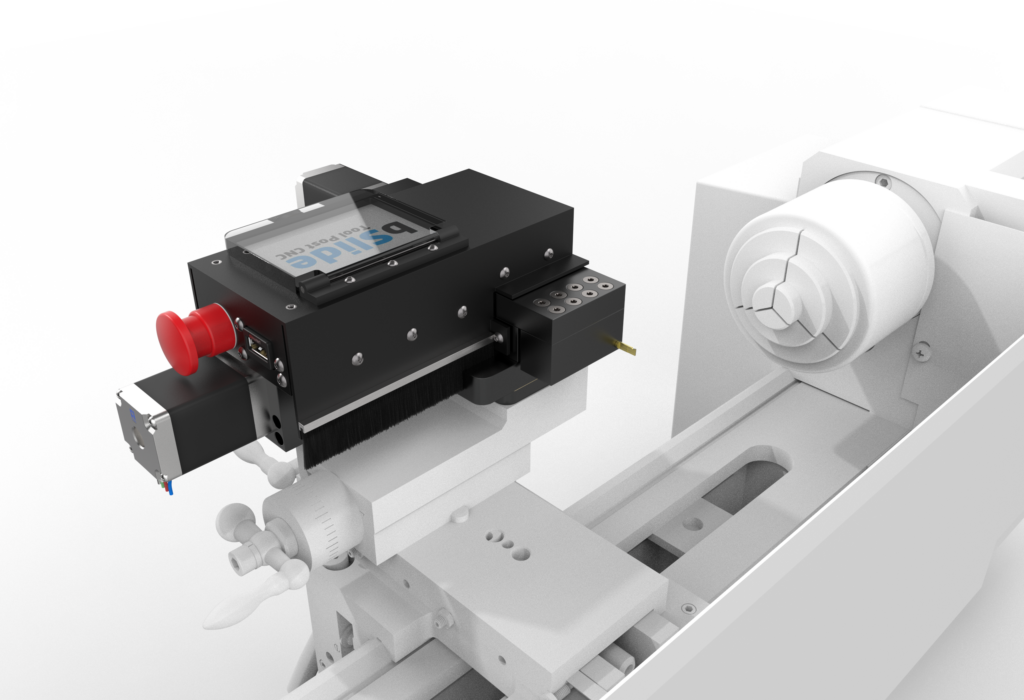

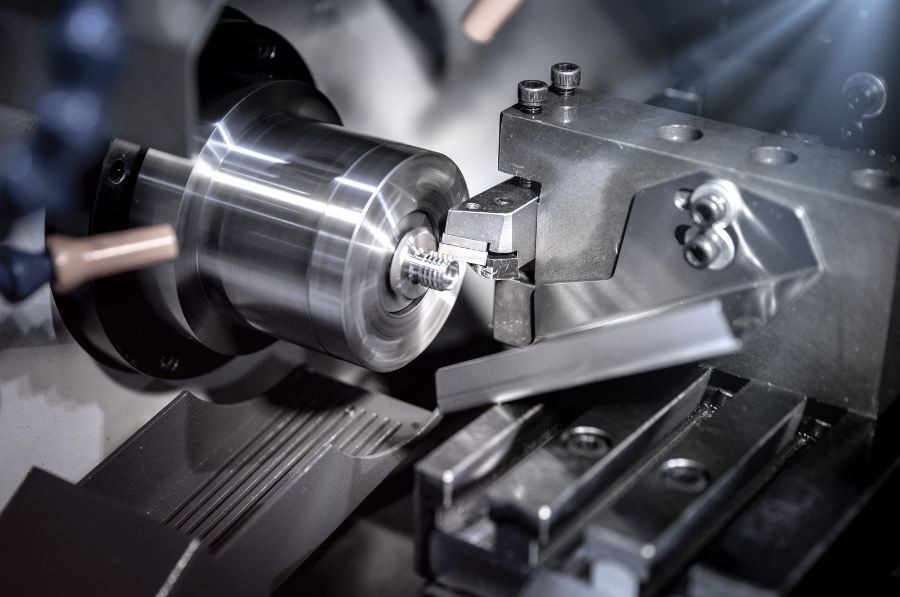

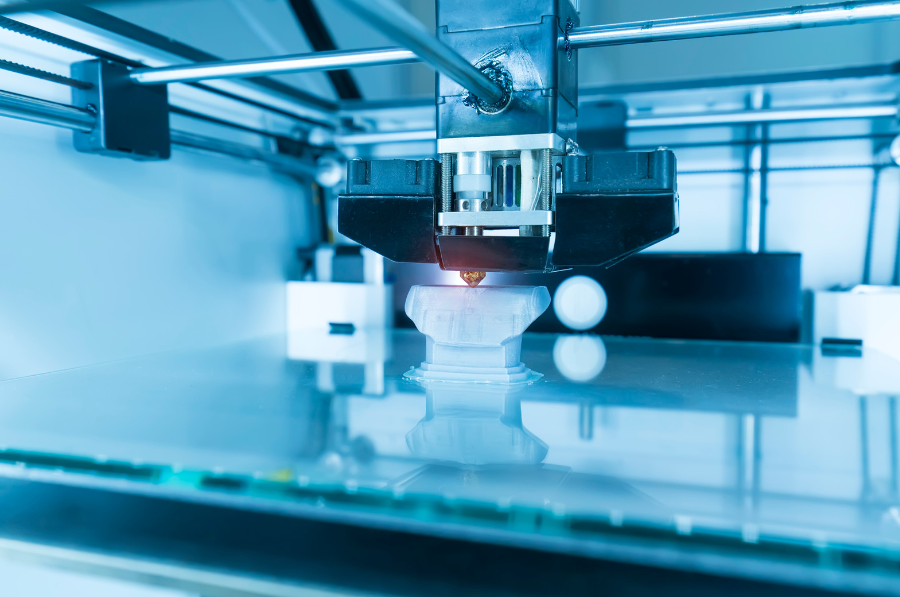

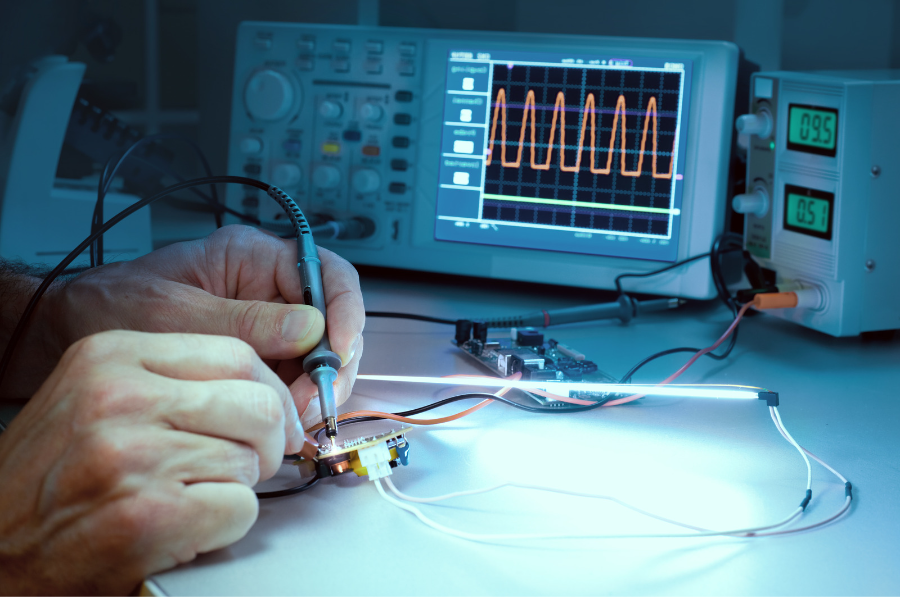

We offer a full suite of product development services to bring your new idea to life. Over the years we have worked to bring critical capabilities in house, so ideation and iteration can happen in the fastest possible cycle time.

7561 Tyler Blvd

Suite 7

Mentor, OH 44060

2023 © Aqua Engineering, LLC. All Rights Reserved.